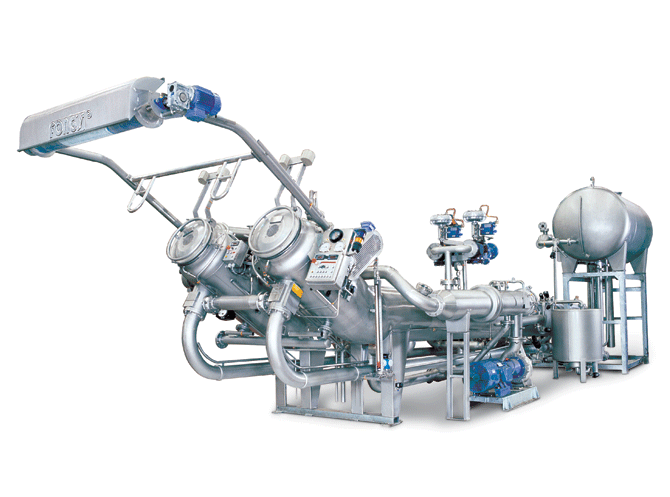

ECO-88 High Speed Dyeing Machine (High Temperature Dyeing)

Add to enquiry basket

Introduction

The ECO-88 High Speed Dyeing Machine is suitable for woven and knitted fabrics, especially the light weight materials and fabrics, which are sensitive to crease marks, such as polyester and microfibres etc. The highly efficient heat exchanger is the ideal supplement to the high fabric speed, which ensures the shortest dyeing cycle.

Advantages

-

High fabric speedThe fastest fabric speed of 600m/min ensures to achieve optimum loading within 2 mintues of fabric turn around time.

-

Fast bath turnover rateThe circulation pump provides high flow rate to sustain the high fabric speed.

-

Long KierThe fabric spreads over the whole length of the kier so that the fabric is not subject to high stack loading, thus reducing the formation of crease mark.

-

Sloped kierIt assists the smooth forward movement of fabric.

-

Upward sloped front kierIt helps lift up the fabric rope from the pile.

-

Reversing nozzleWhen tangling occurs, the reversing nozzle ejects the fabric rope back into the kier to dismantle the tangling automatically.

-

Conveyance tubeFabric rope immerses in the conveyance tube to complete the syestuff exchange for evenness.

-

Rear taper sectionSlows down the liquid and fabric speed after entering into the kier thereby reduces fabric tangling.

-

Seam detector (Optional)Speeds up locating the fabric seam for unloading Fabric tangling alarm device.

Technical Data

-

Design temperature140°C

-

Design pressure3.5bar

-

Heating gradient25°C ~ 130°C, total 27min(dry saturated steam pressure at 7bar)

-

Cooling gradient130°C - 80°C, total 17.5min (cooling water at 3bar, 25℃)