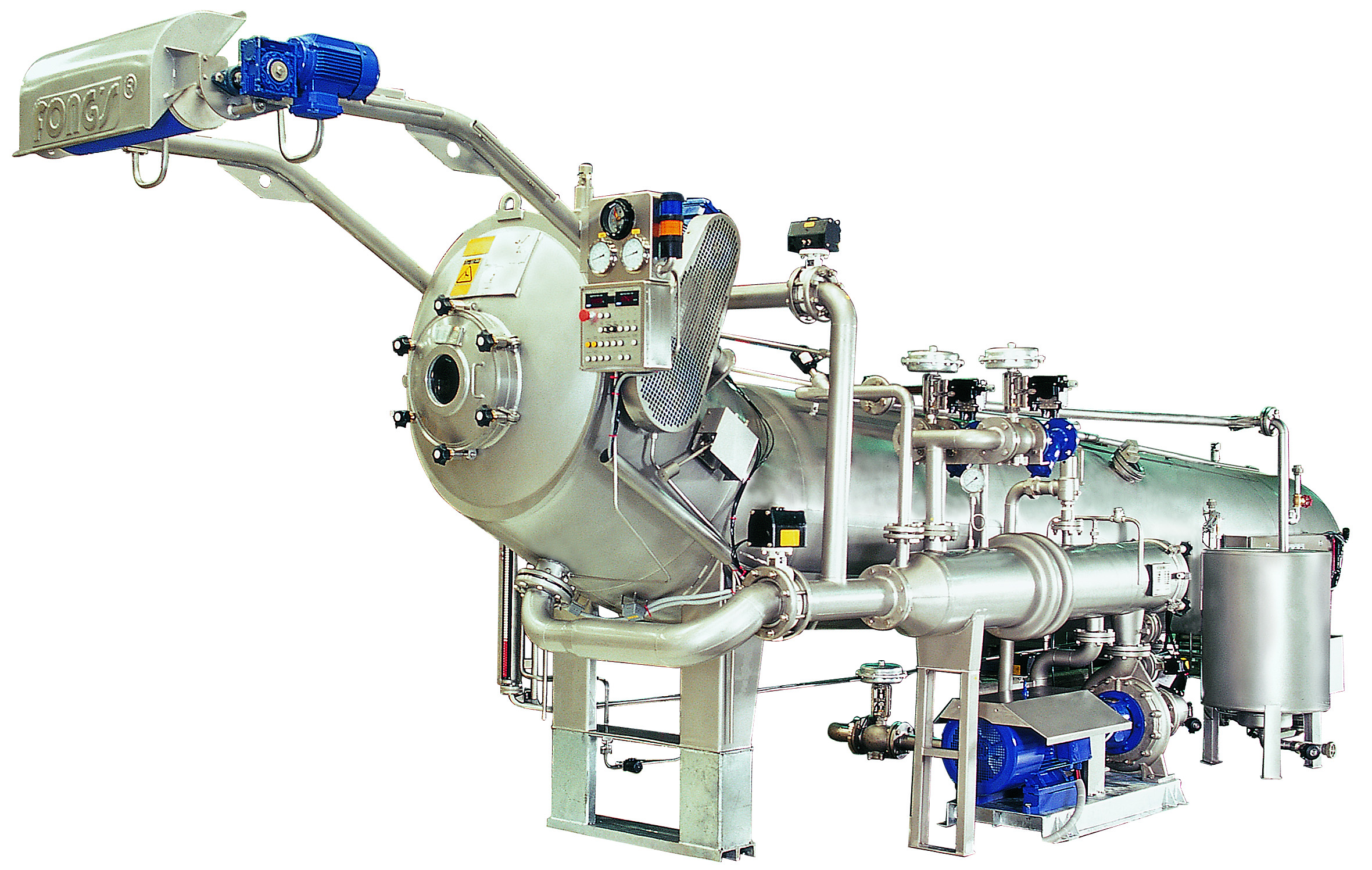

The ECO-88D Double Rope High Speed Dyeing Machine is the prime choice for the processing of light to medium weight woven and knitted goods made from synthetic and blended fiber. Particularly it is suitable for fabric which is sensitive to temperature and the formation of crease marks.The fabric movement inside the storage chamber is well controlled thereby resulting in high fabric speed and minimum tension is exerted on the fabric. The PTFE rod lined bottom provides the smoothest surface in addition to the HydroSki supporting system.

- For the dyeing of light to medium weight fabric in rope form, either tubular or open width.

- Particularly suitable for fabric sensitive to temperature and formation of crease marks.

Polyester, polyamide (nylon), etc.

Light to medium weight fabrics such as wovens, warp knitted fabrics, taffeta, etc.

- Increased capacity to process light weight fabric as two ropes of fabric can be processed in a single kier

- High fabric speed ensures even shades and prevents crease marks formation

- Minimum fabric tension, suitable for stress sensitive fabric

- Gentle and smooth flow of fabrics ensures good fabric finish and quality

- Constant cleansing of fabric surface makes fabric clean, even distribution of temperature reduces crease marks

Depending on machine model,

For fabric weight < 120 g/m, capacity: 1800 – 12000m.

For fabric weight > 120 g/m, capacity: 200 – 1600 kg.

-

Design temperature140°C

-

Design pressure3.5bar

-

Min. Liquor ratiodown to 1:6-8

-

Heating gradient25°C ~ 130°C , total 27min(at dry saturated steam pressure at 7bar)

-

Cooling gradient130°C - 80°C , total 17.5min (at cooling water at 3bar, 25℃)