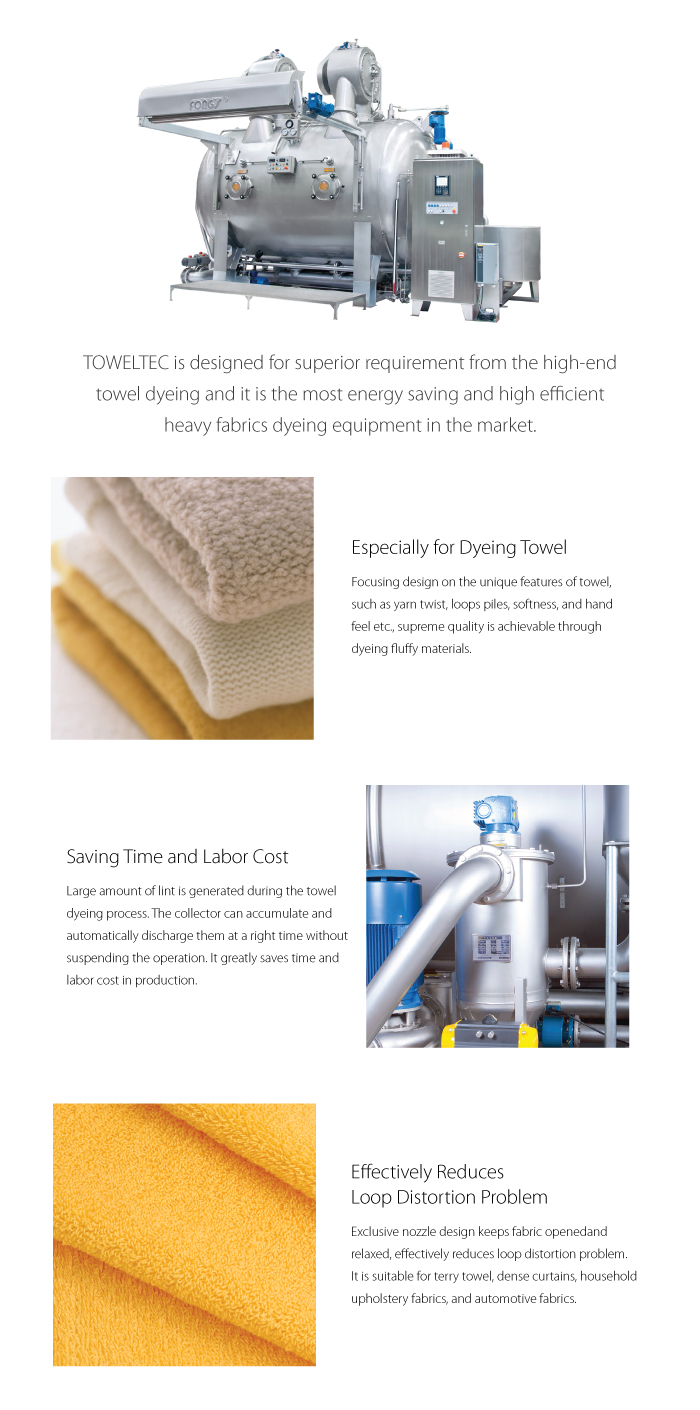

TOWELTEC High Temperature Towel Dyeing Machine

Add to enquiry basket

Collecting chamber

Special body bottom design lowers liquor ratio and the dye liquor circulates better and faster. Lowered machine body and operation height makes the machine more accessible, and reduce workload.

VERTICAL LSD PUMP

Low suction design lowers the liquor ratio; internal filter effectively extend the lifespan.

Vertical Multi-function Stock Tank

Interior heat coils for heating, the circulating pump for mixing and discharge to service tank. inner overflow channel

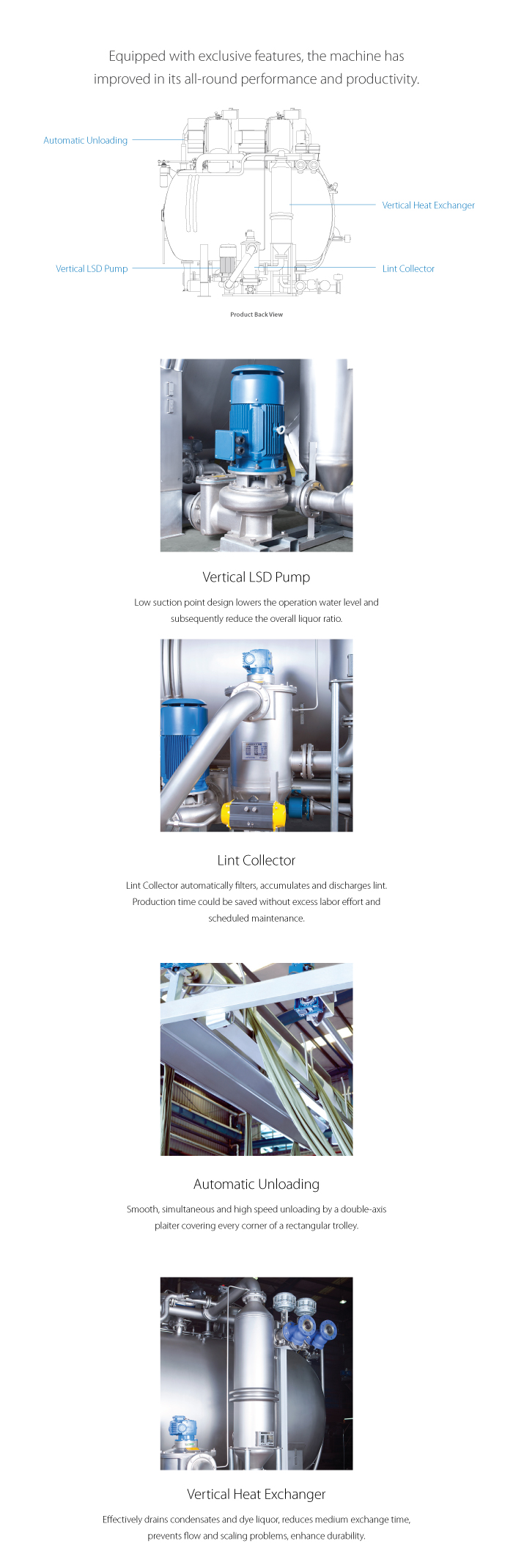

VERTICAL HEAT EXCHANGER

Effectively drains condensates and dye liquor reduces medium exchange time, prevents flow and scaling problems, enhance durability.

FC30EX Program Controller

The new generation of FC30 program together with novel control functions, providing the most cost-effective control.

LINT COLLECTOR

Lint Collector automatically filers, accumulates and discharges lint. Production time could be saved without excess labor effort and scheduled maintenance.

Introduction

TOWELTEC high temperature towel dyeing machine- is designed for superior requirement of the high-end towel dyeing. TOWELTEC is the most energy saving and high efficient heavy fabrics dyeing equipment in the market.

Advantages

-

Suitable fabric weight200~600g/m²

-

Max. capacity per chamberup to 400kg

-

Liquor ratio1:5

-

Suitable forTerry towel, dense curtains, household upholstery fabrics, and automotive fabrics.

-

Eco-friendlyThe most energy saving and high efficient heavy fabrics dyeing equipment in the market.

Technical Data

-

Design temperature140°C

-

Design pressure3.0 bar

-

Heating gradient25°C ~ 100°C approx. 5°C/min

100°C ~ 130°C approx. 2.5°C/min (dry saturated steam pressure at 7bar)

-

Cooling gradient130°C - 100°C approx. 3°C/min

100°C ~ 80°C approx. 2°C/min (cooling water at 3bar, 25℃)