SUPERWIN High Temperature Single Flow Package Dyeing Machine

Add to enquiry basket

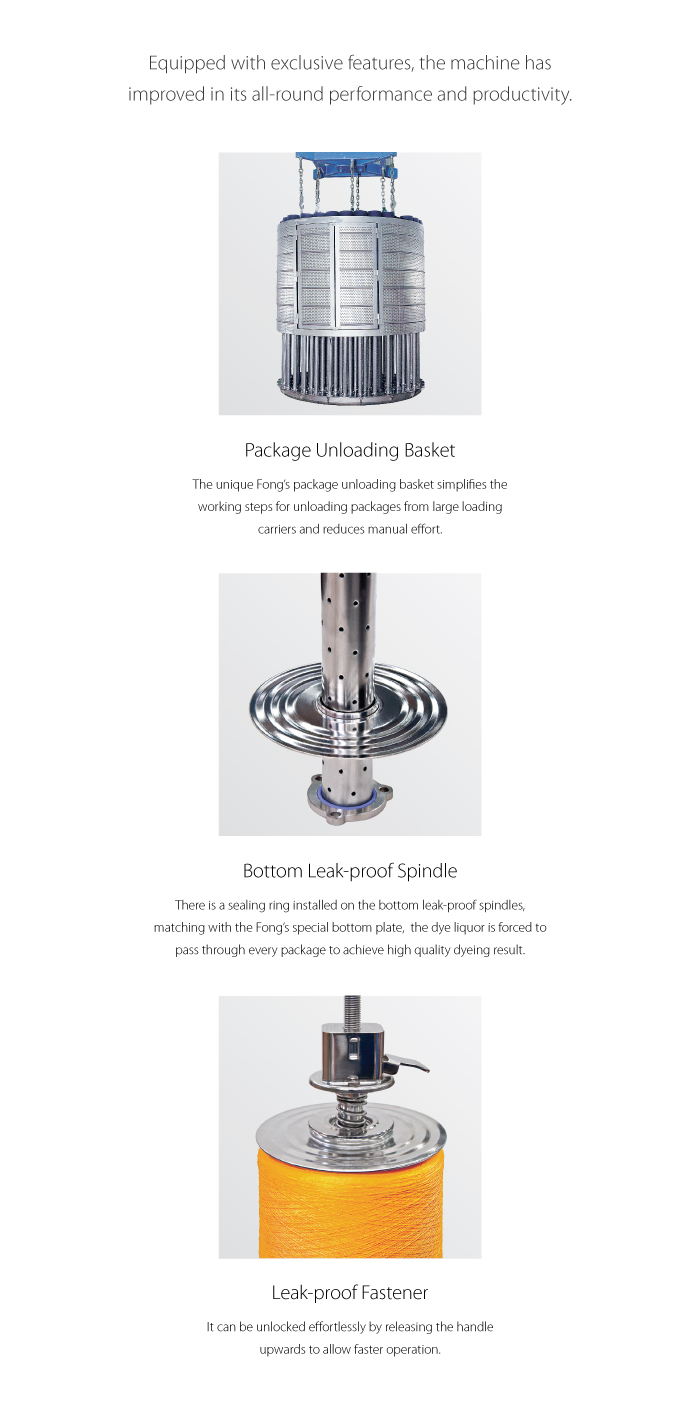

Package Unloading Basket

The package uploading basket is placed on the package carrier before loading package for dyeing. It is lifted up directly with crane after carrier is unloaded from vessel after dyeing. The package unloading basket helps operator by reducing the time for unloading packages thus increase productivity.

Bottom leak-proof spindle

Matching with the Fong’s special bottom plate, the surfaces between spindle, bottom plate and the package are sealed and leak-proof. The dye liquor is forced to pass through every package to achieve high quality dyeing result.

Leak-proof Fastener

Introduction

The Revolutionary wave dyeing technique and intelligent control reduce the liquor ratio close to 1:3. Superwin empowers your production to the leading edge of efficiency and eco-friendliness.

Advantages

-

Single Inside-out flow technologyOnly a sufficient water level at the kier bottom is required to maintain steady pump operation and it is not necessary to have all packages fully immersed with liquor, hence lower liquor ratio is achieved.

-

Innovative wave dyeing technologySpecific period of change in pump frequency, smashing the packages like waves such that it could move under varied pressure to perfect utilization.

-

Intelligent Rinsing (IIR)- Intelligent Control - Avoid manual sampling during rinsing or determining rinsing time by experience.

- High Reproducibility - Accurately determine the water consumption for rinsing, the degree of reproducibility is highly. improved

- Enhanced Efficiency - Any slight changes are clearly shown in real time for analysis, making the drainage progress more organized.

- Eco-friendly dyeing equipment- Operates at liquor ratio as close as 1:3 and compatible to various kind of dyeing applications including light and sensitive color.

-

Pressurized dehydrationThe pressurized dehydration is achieved by injecting compressed air into vessel to squeeze residual water.

-

High Temperature DrainIt can reduce the dyeing time at least 30 minutes and save the cooling water.

-

FC30EX Program ControllerTogether with novel control functions, providing the most cost-effective control.

Technical Data

-

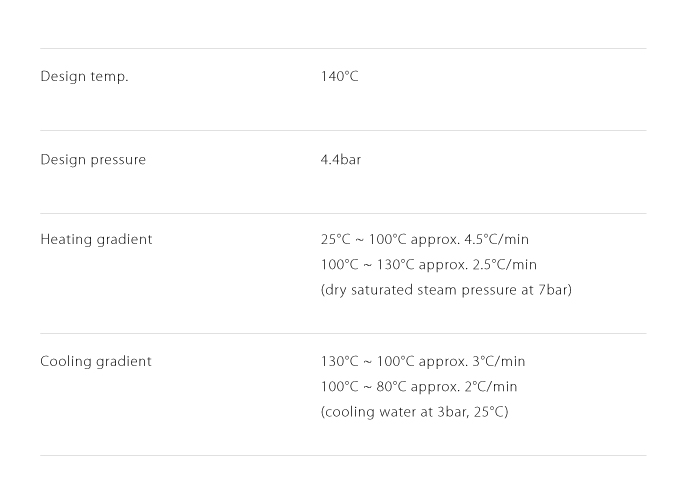

Design temperature140°C

-

Design pressure4.4 bar

-

Heating gradient25°C ~ 100°C approx. 4.5°C/min

100°C~130°C approx. 2.5°C/min (dry saturated steam pressure at 7bar)

-

Cooling gradient130°C - 100°C approx. 3°C/min

100°C ~ 80°C approx. 2°C/min (cooling water at 3bar, 25℃)