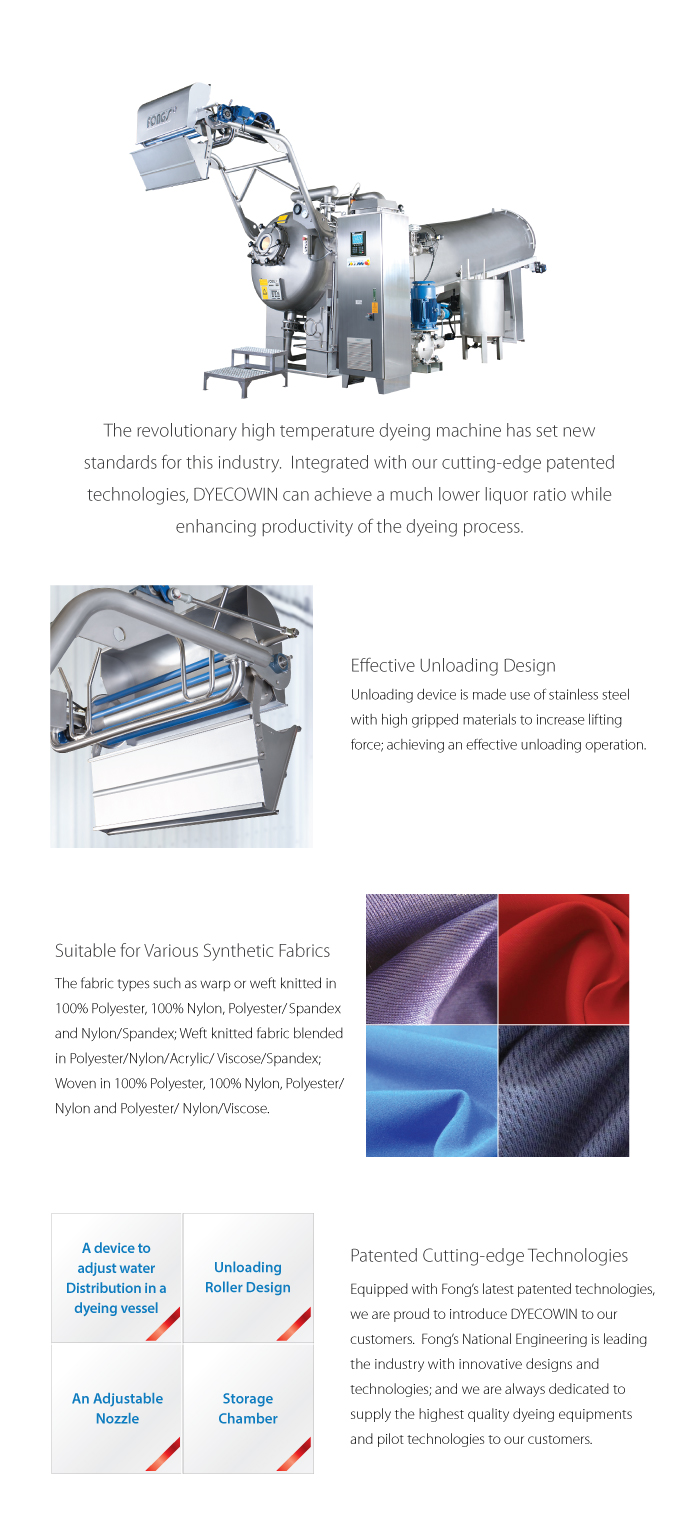

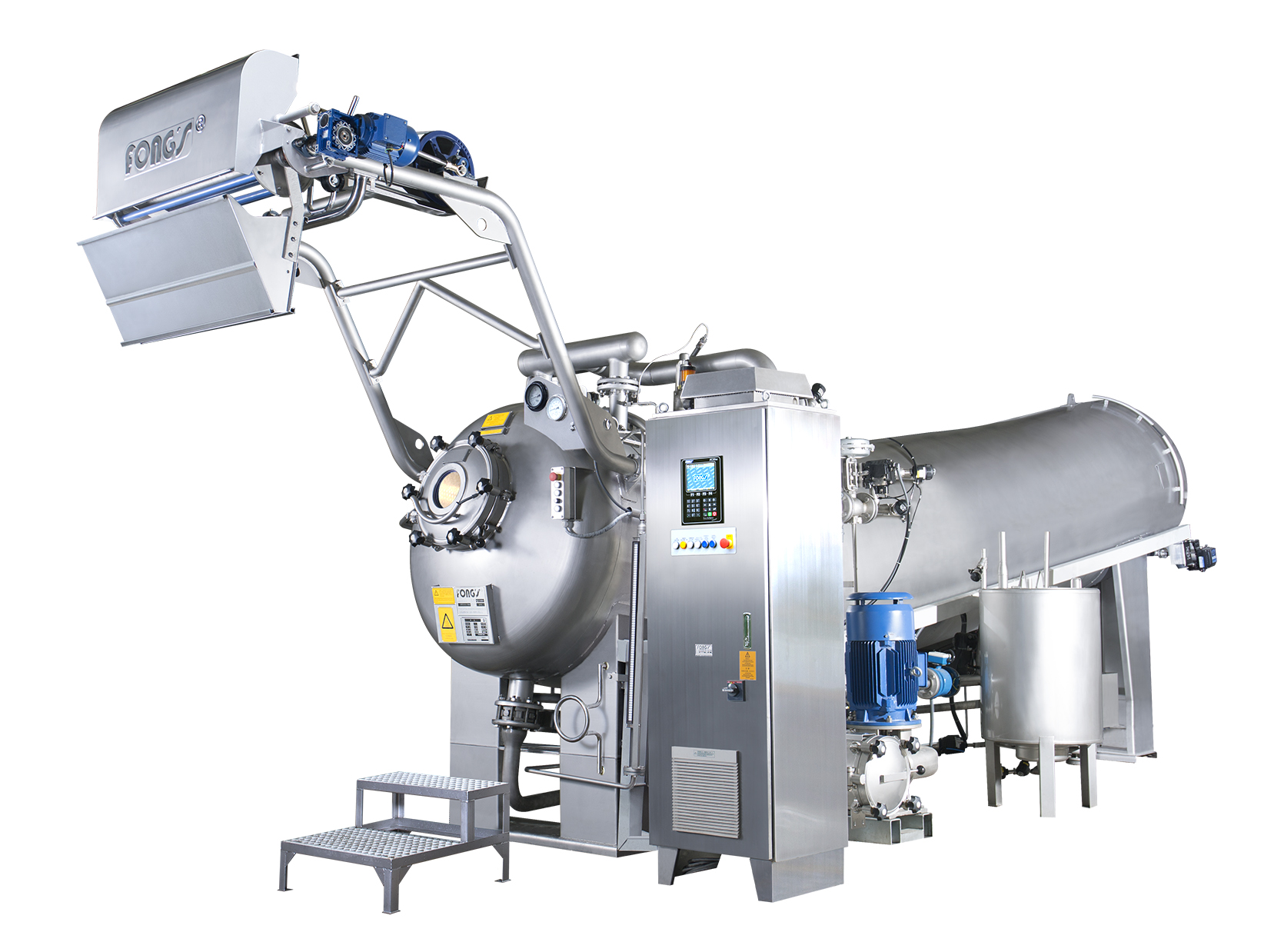

DYECOWIN High Temperature Dyeing Machine

Add to enquiry basket

Introduction

The revolutionary high temperature dyeing machine developed by Fong’s has set new standards for this industry. Integrated with our cutting-edge patented technologies, DYECOWIN can achieve a much lower liquor ration while enhancing productivity of the dyeing process.

Advantages

-

Effective Unloading DesignUnloading device is made use of stainless steel with high gripped materials to increase lifting force; achieving an effective unloading operation.

-

High Fabric SpeedFabric speed can reach up to 600m/min for light fabrics; increasing the load capacity while maintains outstanding dyeing results.

-

Suitable for Various Synthetic FabricsDYECOWIN is recommended to handle fabrics with weight up to 350g/m. The fabric types such as warp or weft knitted in 100% Polyester, 100% Nylon, Polyester/Spandex and Nylon/ Spandex; Weft knitted fabric blended in Polyester/Nylon/Acrylic/ Viscose/Spandex; Woven in 100% Polyester, 100% Nylon, Polyester/Nylon and Polyester/Nylon/Viscose.

-

Patented Cutting-edge TechnologiesEquipped with Fong’s latest patented technologies, we are proud to introduce DYECOWIN to our customers. Fong’s National Engineering is leading the industry with innovative designs and technologies; and we are always dedicated to supply the highest quality dyeing equipment and pilot technologies to our customers.

-

FC30EX Program ControllerOur latest generation program controller - FC30EX is equipped with a 6.5-inch, 640x480-pixel, TFT color LCD display. Together with novel control functions, it is the most cost-effective control. FC30EX can also integrate with our Viewtex and THEN-TDS central computer system, providing a comprehensive control management.

Technical Data

-

Design temperature140°C

-

Design pressure3.5 bar

-

Heating gradient25°C ~ 100°C approx. 5°C/min

100°C ~ 130°C approx. 2.5°C/min(dry saturated steam pressure at 7bar)

-

Cooling gradient130°C ~ 100°C approx. 3°C/min

100°C ~ 80°C approx. 2°C/min(3bar cooling water at 3bar, 25°C)