TECWIN High Temperature Dyeing Machine

Add to enquiry basket

Introduction

TECWIN is designed to satisfy the ever-changing market demands. Apart from equipping with the superior designs of the last generation, some new novel designs are incorporated in this new machine. Both reliability and applicability of the machine are improved.

Advantages

-

Front Spray NozzleIt improves the degree of dye liquor interchange before the fabrics entering the main nozzle. The color balance and quality of fabric can then be enhanced.

-

Manually Operated FilterAn effective water collection is designed to improve dye liquor circulation effect. As the fabric lint and residues can be effectively filtered, production quality can be enhanced.

-

Diversity of ModelThe models providing different capacities from 1 to 8 tubes to satisfy the requirements of different customers' need more flexibility and efficiency. With using high quality 316Ti/1.4571 stainless steel approved by international standards as major material, the TEC series puts you on the world's leading edge.

-

Patented Cutting-edge TechnologiesEquipped with Fong’s latest patented technologies, we are proud to introduce TECWIN to our customers. Fong’s National Engineering is leading the industry with innovative designs and technologies; and we are always dedicated to supply the highest quality dyeing equipment and pilot technologies to our customers.

-

FC30EX Program ControllerOur latest generation program controller - FC30EX is equipped with a 6.5-inch, 640x480-pixel, TFT color LCD display. Together with novel control functions, it is the most cost-effective control. FC30EX can also integrate with our Viewtex and THEN-TDS central computer system, providing a comprehensive control management.

Technical Data

-

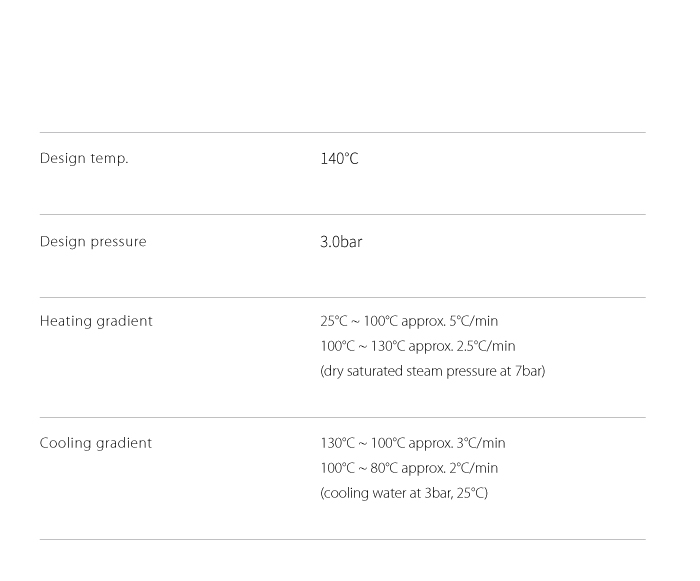

Design temperature140°C

-

Design pressure3.0 bar

-

Heating gradient25°C ~ 100°C approx. 5°C/min

100°C ~ 130°C approx. 2.5°C/min(dry saturated steam pressure at 7bar)

-

Cooling gradient130°C ~ 100°C approx. 3°C/min

100°C ~ 80°C approx. 2°C/min(cooling water at 3bar, 25°C)